AnyPlan3D Dynamic Production Operations

AnyPlan3D is a single suite of capabilities created to seamlessly connect and manage multiple facets of your organizations production operations. Because your business is not static, the capabilities required to support the organization should not be either. Create and analyze multiple scenarios, coordinate with key stakeholders in relevant time, and execute with assurance.

Analyze

Analyze and identify opportunities for investment and improvement

Organize

Manage multiple scenarios stakeholders and contributors from anywhere at anytime

Execute

Confidently Cascade Plans, Objectives and KPI’s to you organization

Streamlining and integrating these foundational operational processes will yield measurable gains in production volumes and cycle time efficiency. Additional benefits are realized by automating well and equipment performance management systems. These systems apply petroleum engineering science to transform, in relevant time, online oilfield measurements into knowledge that improves production volumes, decision speed and decision quality.

Production Management

The AnyPlan3D Production Performance Monitoring solution provides insight into the underlying performance of production management processes that allow:

1. Measuring the health of production performance that provides unique insight into the effectiveness of production management processes.

2. Leading indicators that point to the underlying drivers of production performance

3. A breakdown of the rolled-up production numbers, identifying specific areas for improvement.

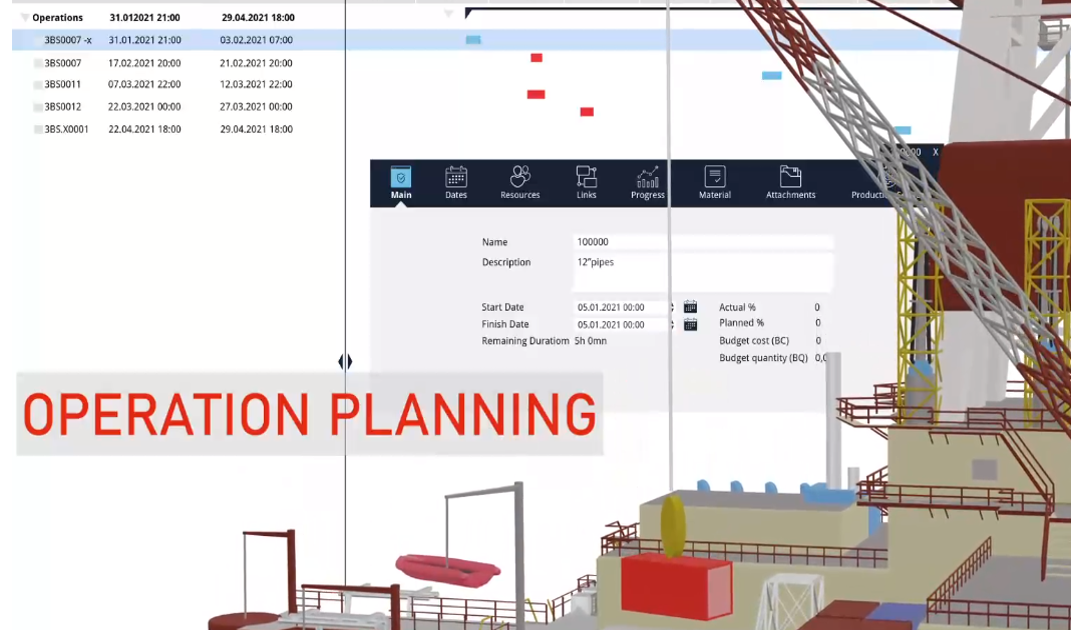

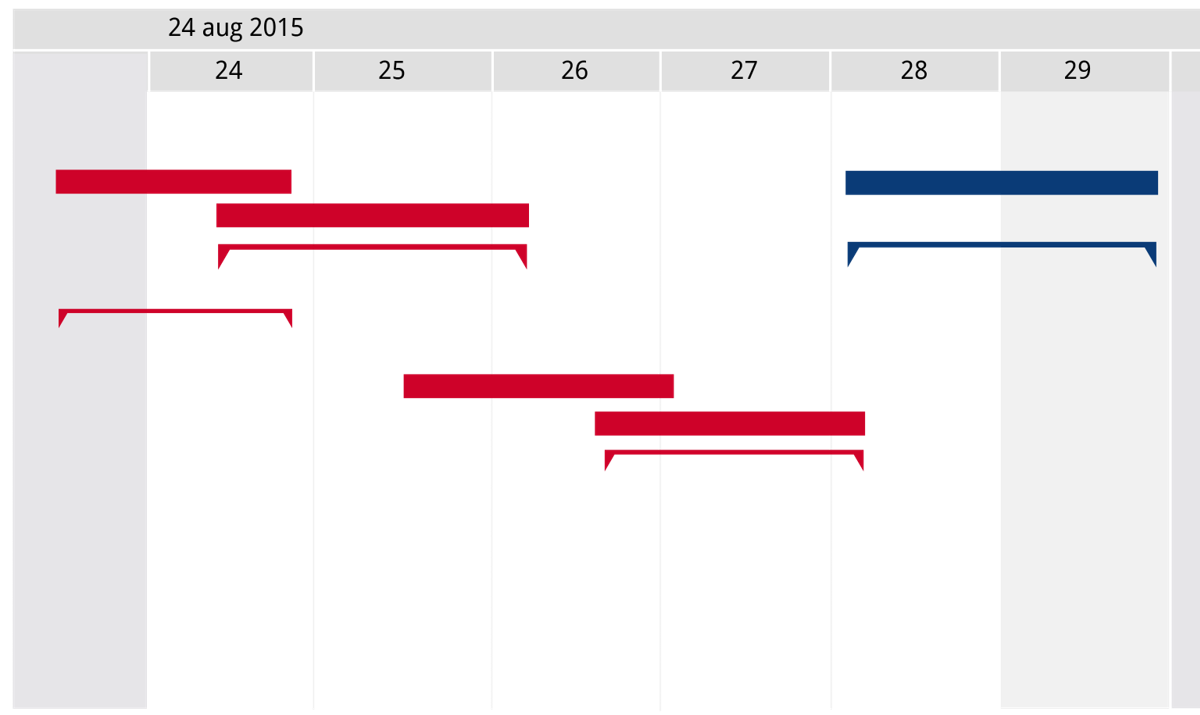

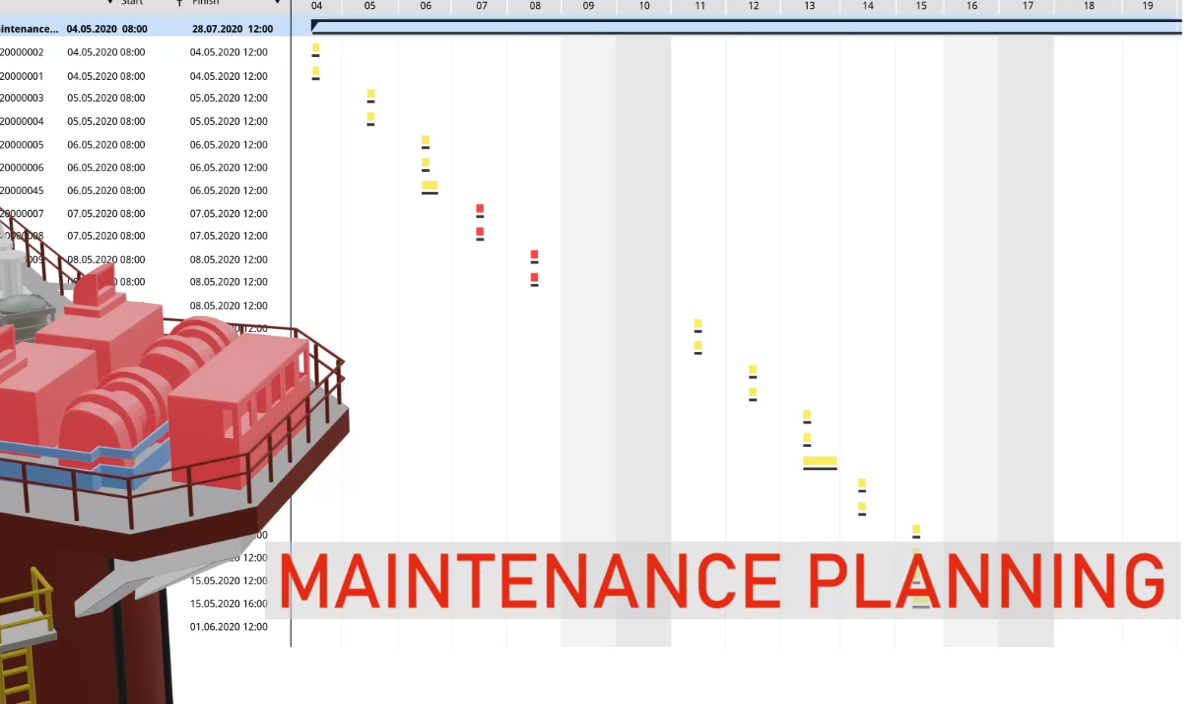

Integrated Activity Planning

Integrated Activity Planning (IAP) is the process that consolidates activities across multiple functions to be carried out into one plan. It maximizes what can be achieved from a defined set of resources, within a given time frame, and in consideration of known constraints. IAP is a consolidated plan with different time horizons that allows planners and engineers to have a forward-looking view of the activities, enabling the plan to be optimized over time and aligned to the asset requirements.

Generally, the scope of IAP includes the following types of activities:

1. Activities which cause a production deferment.

2. Activities which result in a production gain.

3. All activities that have a significant impact on constrained or shared resources (e.g., human footprint, requires special equipment or place a restriction on other activities such as crane maintenance or heavy lifting)

The table below details the benefits that IAP enables and the resulting potential impact.

Production Forecasting

The objective of Production Forecasting is to develop a clear and common understanding of the true potential of the asset and a shared ownership of the technical potential to build a realistic production forecast considering discrepancies from string to terminal and deferments.

The Production Forecasting processes ensures that an operating company stays focused on optimizing hydrocarbon production in both the short and long term

This in turn will enable the operating company to:

1. Maintain clear visibility of the various constraints throughout the production system that are limiting output

2. Drive critical review on these constraints and identification on what is needed to remove them

3. Build sufficiently challenging production targets that are ultimately achievable

4. Develop integrated action from the entire Asset Team spanning surface and subsurface

Opportunity Management

Opportunity Management is the identification, evaluation, prioritization, planning, scoping, execution and tracking of projects across the various functions with the objective of resolving constraints and unlocking potential for operating assets.

Opportunity Management is comprised of four key processes:

AnyPlan3D Opportunity Management system uses a single platform for all opportunity capture, prioritization, planning and tracking. At the same time, involvement and ownership from all levels are required to ensure accountability with frequent updates and challenge to ensure the delivery of opportunities.

1. Identification: Recognizing solutions to resolve constraints

2. Evaluation and Prioritization: Development of business case and prioritization against other initiatives to manage resource constraints effectively

3. Planning and Scoping: Preparing and establishing the groundwork on opportunities to ensure on time delivery of the expected potential to achieve annual targets

4. Execution and Tracking: Improving visibility of timing and actual results as compared to planned estimates. This in turn will drive accountability and operational optimization based on lessons learnt from these cases

Risk and Issue Management

The Risk & Issue Management process is focused on identifying and mitigating operational and financial risks associated with opportunities to increase an assets production and is closely related to the Opportunity Management process. The process provides a formal channel to receive consultation and support from experts in the region, headquarters, and suppliers. Data integration with the Production Performance Improvements process consolidates the detailed and current information regarding major risks and issues. The consolidated information factors into the estimated unplanned production deferment where management decides on mitigation recommendations during formal meetings.

Hydrocarbon Choke Model

The Hydrocarbon Choke Model allows visualization and analysis of opportunities that aid operators managing and reaching production efficiency targets. The Hydrocarbon Choke Model allows the establishment of the unconstrained production capacity of the hydrocarbon value chain, constraints in the system that prevent the achievement of the maximum production, and proposed projects to deal with these constraints.

The Hydrocarbon Choke Model is a fundamental component of Production Excellence initiatives and it is a key input to Activity Planning, Production Forecasting, Loss Management, Opportunity Management, and Risk & Issue Management.

Surveillance and Analytics

Surveillance and Analytics leverages a variety of data sources. These range across both cloud and on-premises sources, and include:

1. On-premises databases – Live connectivity to SQL Server Analysis Services, Azure SQL. And using the Enterprise Gateway to connect to other database solutions such as Oracle and others

2. Custom data sources – Connect to any data source you need it to thanks to its extensibility via REST APIs. This includes both proprietary corporate data sources, as well as external data services.

3. Azure services – Integrated with SQL Azure and Stream Analytics.